THE PRINCIPLE OF ULTRASONIC WELDING |

|

By the high-frequency vibration imposed on the welding thermoplastic parts so as to increase the friction between the plastic work-piece surface and the internal elements. The temperature on the contact will be raised rapidly. When the temperature is raised up high enough to melt the plastic, the contacted surfaces between the welded parts will increase a melting layer. When the vibration stops, the welded parts will be solidified and complete the welding.

|

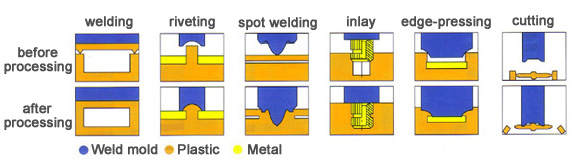

THE CRAFTWORK OF ULTRASONIC WELDING |

|

| |

THE WELDING SITUATION OF DIFFERENT PLASTIC MATERIAL |

|

| ¢Å ABS |

| ¢Æ AETAL |

| ¢Ç ACRTLICS |

| ¢È CELLULOSICS |

¢É CYCOLOY-

8CYCOVIN |

| ¢Ê KYDEX |

| ¢Ë NORYL |

| ¢Ì NYLON |

| ¢Í PC |

| ¢Î PE |

| ¢Ï PP |

| ¢Ð PS |

| ¢Ñ POLYSULFONE |

| ¢Ò PVC |

| ¢Ó SAN |

| ¢Ô POLYESTER |

| ¢Õ XT-POLYMEP |

|

| ¢Å |

¢Æ |

¢Ç |

¢È |

¢É |

¢Ê |

¢Ë |

¢Ì |

¢Í |

¢Î |

¢Ï |

¢Ð |

¢Ñ |

¢Ò |

¢Ó |

¢Ô |

¢Õ |

|

|

|

BESTWELDING |

|

GOOD WELDING |

|

BAD WELDING |

|

|

|

| |

Design show of the welding surface |

|